EVA features and product application

Ethylene and vinyl acetate copolymers are the most important products in ethylene copolymers, and are generally referred to as EVA in foreign countries. However, in China, ethylene and vinyl acetate copolymers are classified into EVA resin, EVA rubber and VAE emulsion according to the difference in vinyl acetate content. Products with a vinyl acetate content of less than 40% are EVA resins; products with a vinyl acetate content of 40% to 70% are very flexible; and have elastic characteristics. EVA resins in this range are sometimes referred to as EVA rubber; vinyl acetate content is 70%. In the range of ~95%, it is usually in the form of an emulsion called a VAE emulsion. The appearance of the VAE emulsion is milky white or yellowish.

Features of EVA foam: Water resistance: closed cell structure, no water absorption, moisture resistance, and good water resistance.

Corrosion resistance: resistant to corrosion by seawater, oil, acid, alkali and other chemicals, antibacterial, non-toxic, odorless, non-polluting.

Processability: no joints, and easy to hot press, cut, glue, fit and other processing.

Anti-vibration: high resilience and high tensile strength, high toughness and good shock/cushion performance.

Insulation: heat insulation, heat preservation and low temperature performance, can withstand severe cold and exposure.

Sound insulation: closed cells, good sound insulation.

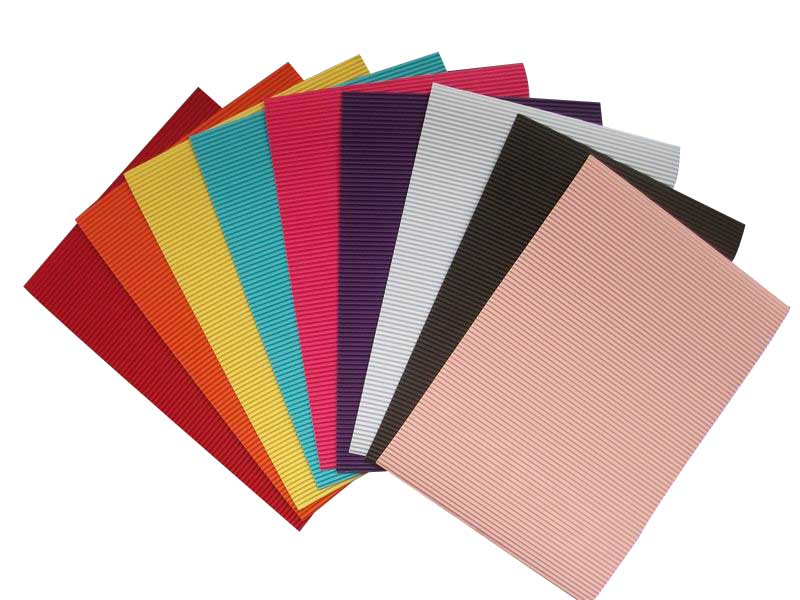

Product application range: Eva foam sheet, Household appliances, hardware tools, toys, handicrafts, travel products, stationery, cosmetics; skates: lining materials for sports shoes, sports insoles, luggage back pads, surfboards, mattresses; sports protective gear, car interiors, shoes Material lamination; base material for high-grade foam tape products; ice storage, cold-proof construction, light pad, sun visor material; shock-proof buffer packaging for electrical appliances, precision instruments, instruments and other electronic products.